My ranch job is to be the morning goat milker, so every morning at 6am, I head down to the barn and greet the ladies. If it’s been a rainy night, they’re usually hanging out in the barn.

Then I head into the middle room of the barn, where the milk is stored. My first task is to put a filter sleeve onto a holder; the milk gets passed through this filter before it goes into the storage tank.

Then that piece gets inserted into the big stainless steel cylinder, and attached via a big ring clamp. Getting this clamp on is the hardest part of the whole job, especially for someone with klutzy fingers. You have to hold the whole thing up against the tube while futzing the clamp into place. Fortunately, I’m getting pretty good at it!

When that’s done, I add more tubing with clamps to feed the milk into the storage tank.

Then I’m done in this room. Time to head into the milking part of the barn! First, I make sure everything is clamped and stoppered at the the receiving tank, which has been draining after the last cleaning. During milking, the milk goes here before it’s sent to the storage tank.

As you can see, so far it’s a lot of equipment manipulation and very little goat contact!

The next step is to disconnect the cleaning cups and close all the valves, getting the milking cups ready for the big event.

Finally, I make a trip out to the grain silo and get a couple buckets of rolled barley. This gets placed in the trough; the girls stick their heads through the stanchions for their morning treat.

Finally…time to get the goats! My favorite part of the morning is greeting my good buddy, Rozena Quail.

Rozena Quail is a big half-Nubian elder, often ill-tempered with other goats, and never seems to get enough to eat to satisfy her. She gave us the only set of triplets this year and gives bountiful milk. Despite the fact that I gave her triple the rations of any other goat in the pens, she was constantly hungry. But she seems to remember that I was good for an extra scoop of grain. Every morning, she comes right up to sniff me over thoroughly and get a hug. We are souls sisters for sure.

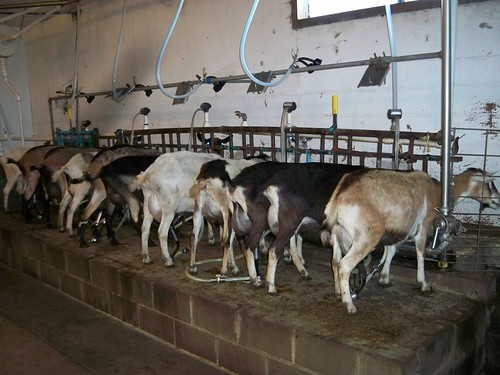

The goats go into a holding pen. Those that aren’t on the first string wait here until their turn. We can milk up to eleven goats in a string; there are two strings on our milk line at the moment (21 milking goats).

If the girls are feeling cooperative, they run into the barn and stick their head into the stanchions and begin eating, and we lock the stanchions closed so they are held in place during breakfast.

But there are a couple more steps before the actual milking begins. Here’s the tools we use during the milking procedures:

Before we start milking, we have to strip, dip, and wipe. After the milking machine gets most of the milk, we finish each goat by hand…this helps prevent stress on the teats which can lead to mastitis.

The blue container with the brown strainer is used to "strip"…we get a squirt from each teat by hand and inspect it to make sure everything looks right. Then we use the blue cup to "dip" each teat in an iodine solution. Then we wipe off the excess iodine from each teat.

The orange bucket is used to milk out each goat by hand at the end. We dump the milk into the metal strainer, which has a paper filter to remove any dirt or hair. Then we do a final dip using the green cup, with another iodine solution.

Here’s a photo during the first dip, after the strip and before the wipe:

Finally, we’re ready to milk! There are five stations, so we milk in pairs, attaching the machine to one goat, and then moving it over to the other goat when she’s finished. (At between the last two stations, we have an extra goat, so we use whichever one is available first for her. Don’t ask me why there are eleven stanchions and five stations.)

The milking machine is quite loud! Here’s a little video of it.

During and after the machine milking, we might do herd care like hoof trimming or applying salve to chapped udders. We also finish milking each goat by hand; milking them to the very end can put extra strain on the teats and contribute to mastitis. So you have to keep a close eye on the tubes and udders during milking, to watch for when the milk flow begins to slow down, and move the cups from one goat to another until they are all milked.

After finishing by hand, the teats get one more dip in a sanitzing solution. Then the ladies are released to go back outside. Rozena, of course, sometimes wanders around the barn looking for more to eat until I lead her out. She even seems to have a knack for releasing herself out of the stanchion when she is done. I haven’t figured out how she does it, and she’s done it from mulitple stanchions. Smart goat.

I put more grain down for the second string, and the whole process is repeated until they, too, are sent out and down the ramp, back to the pasture.

I always gassho to the goats after the final string exits, grateful for their gift of milk and and the opportunity to work with them.

Then it’s time for cleaning. The big paper filters sleeve is removed and the tubing setup is reconfigured to direct the flow to and from the sink, instead of from the goat udders to the storage tank.

We put a powdered cleaner into the sink and fill it with hot water. This gets run through the entire system for five minutes.

Then it’s all drained out, and a second rinse cycle is done with “Acid Du”, an acid and deposits remover to keep the lines absolutely clean. Then everything is disassembled and left in the sink, ready for the evening milker.

The whole process, with two strings, takes about two hours.

You can also view this as a Flickr photo set. There’s a few more photos there.